And so it goes, I was reviewing for some time which robotics platform I could buy or build to get my hands dirty.

As I started looking at models in the few hundred dollar range as a base for development, I soon moved into looking at the over a thousand dollar humanoid range specs. But the lack of higher imaging and processing capabilities made me continue looking into higher and quite unaffordable ranges… Just looking…

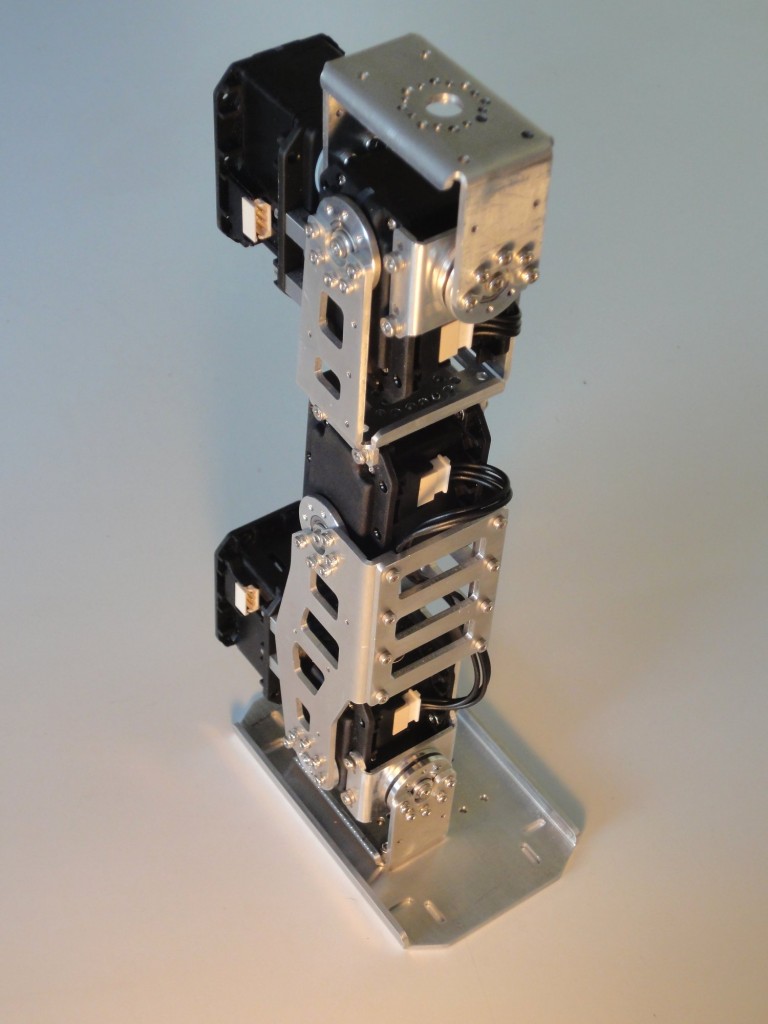

And then I stumble with DARwIn-OP platform which was developed by the robot manufacturer Robotis in collaboration with Virginia Tech, Purdue University, and University of Pennsylvania.

It is an open source humanoid platform with an on-board PC running Linux (Ubuntu) with good enough power, network capabilities, and even an on-board Webcam for image processing. The robot is not cheap at 12,000 USD. But it is open source and by that I mean:

- The mechanical specs and designs are open source and published online in sourceforge.

- The Fabrication and Assembly Manuals are also published online with the specs.

- And also the Control Software source code is open source and published, even the ISOs with Ubuntu and the software installed.

So you can make a DARwIn-OP robot clone. You still need to buy the servos (20 minimum) and the electronics. But it was designed to be cloned.

The robot is not too new, the University of Pennsylvania has won the RoboCup’s kid-size league for the last 3 years with a DARwIn-OP team. It has been used in many Universities. Also, there is a DARwIn-OP clone under development using 3D printing at about half the cost, you can read Michael Overstreet’s blog. Simulators are also available. It is programmed in C++ and a few upgrades are available like feet with pressure sensors and gripper arms.

So I gathered enough arguments to convince myself to make a DARwIn-OP clone (of course I minimized aspects like the cost of its sophisticated and expensive Dynamixel MX-28T servos which have to be bought, 20 of them… but that can be stretched as the building process takes place).

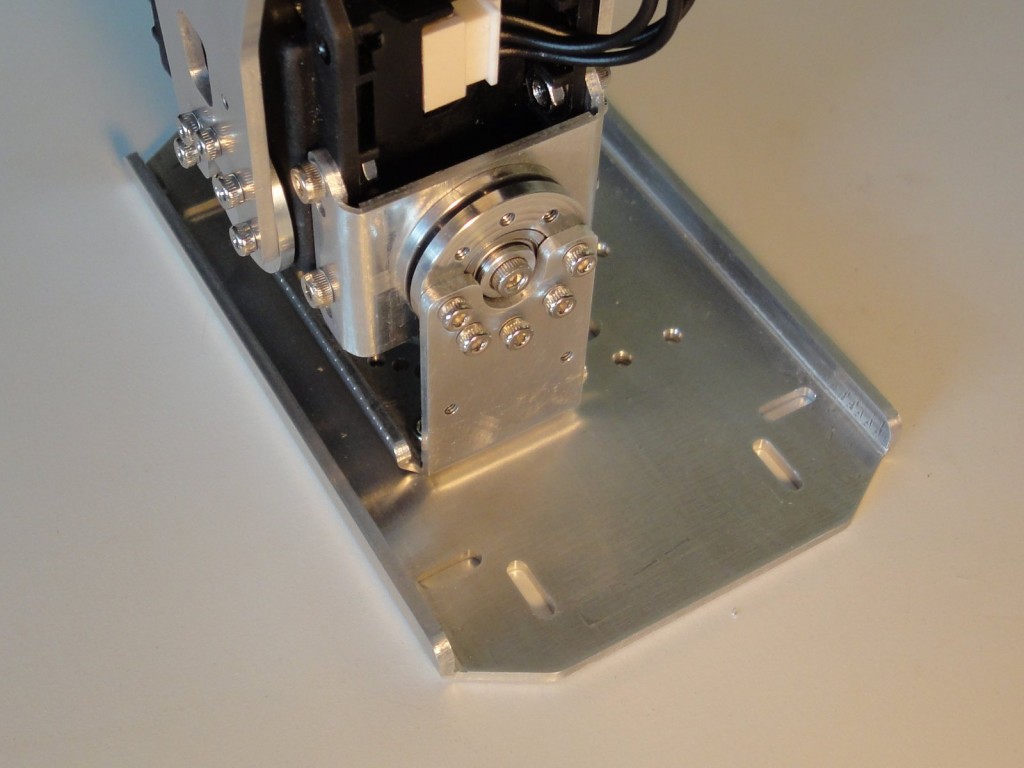

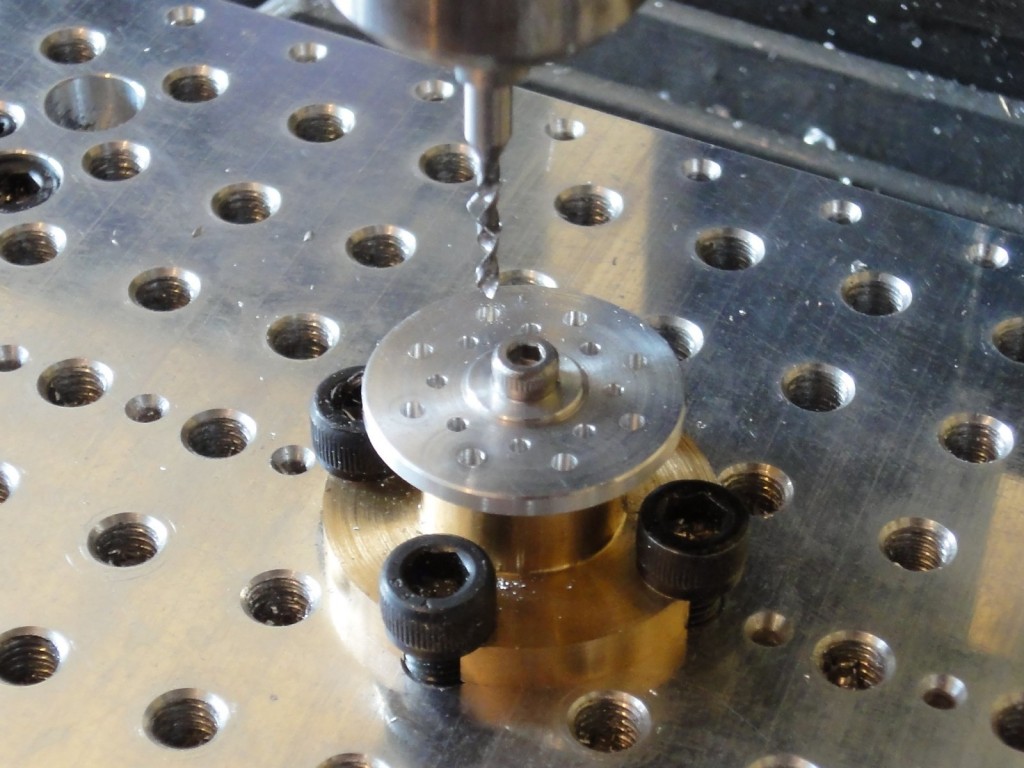

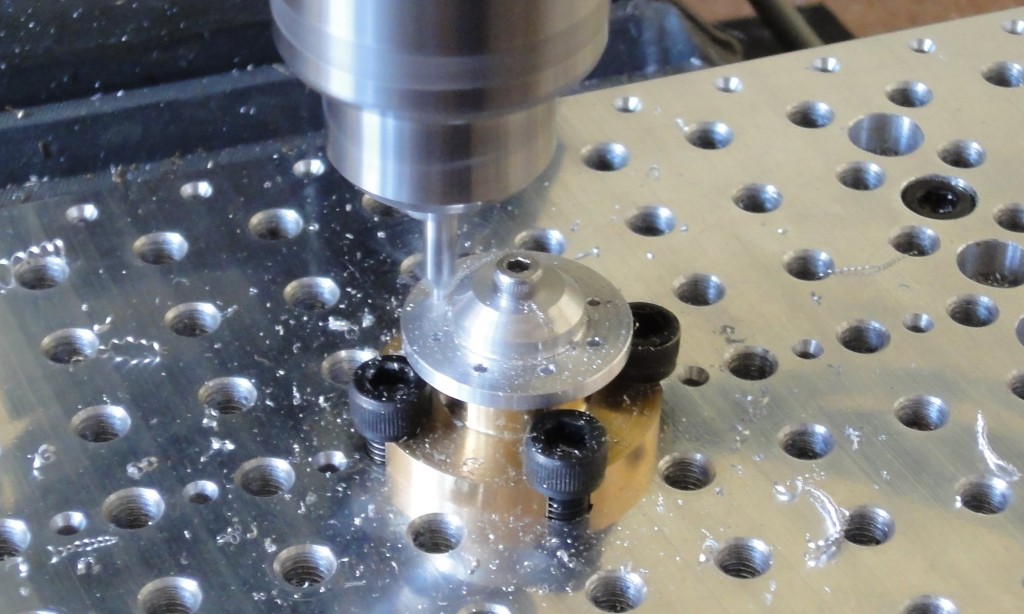

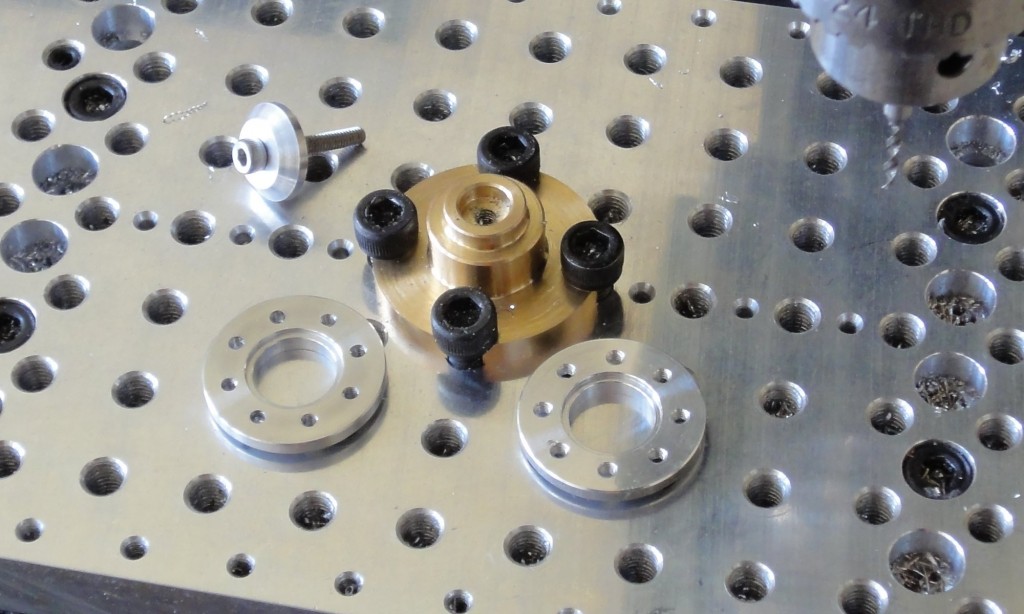

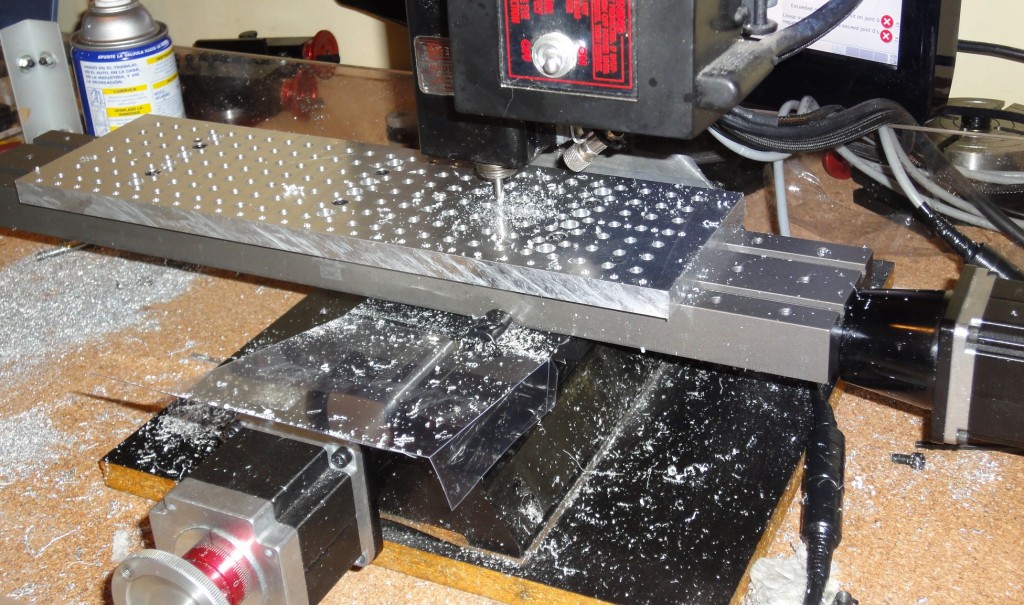

I intend to make the structural frame from aluminum as original designed, using hobbyist CNC tools. I’ll leave 3D printing for the external plastic covers. For the electronics, I’ll later decide if I’ll use the original Atom motherboard or I’ll do an upgrade to a more powerful one, maybe with an ARM cpu, the Cortex-A15 should soon be available in a usable motherboard size. I decided not to replace the servos with a cheaper alternative, there are too many variables already floating around to add more complexity.