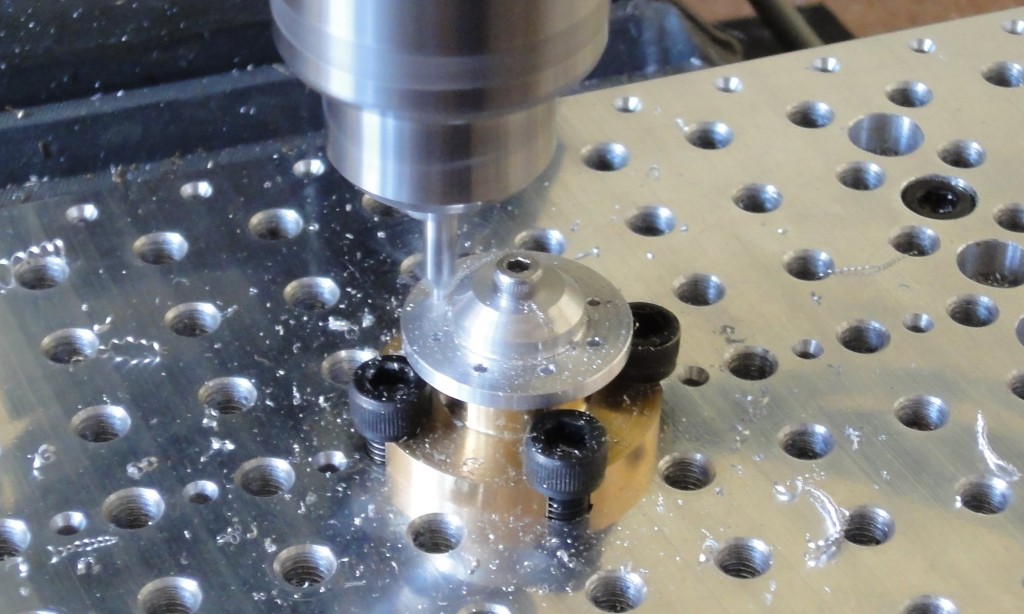

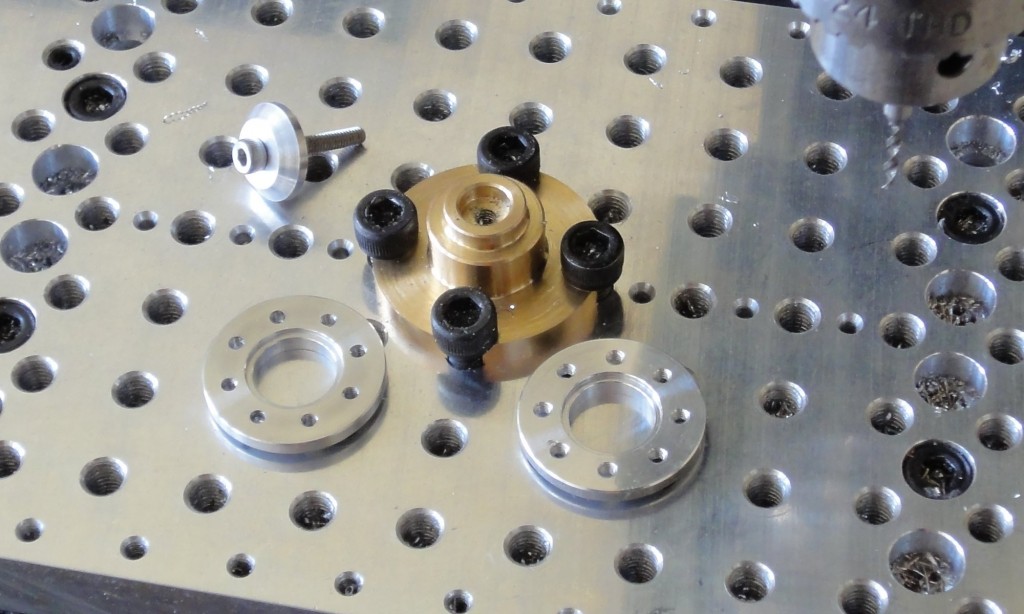

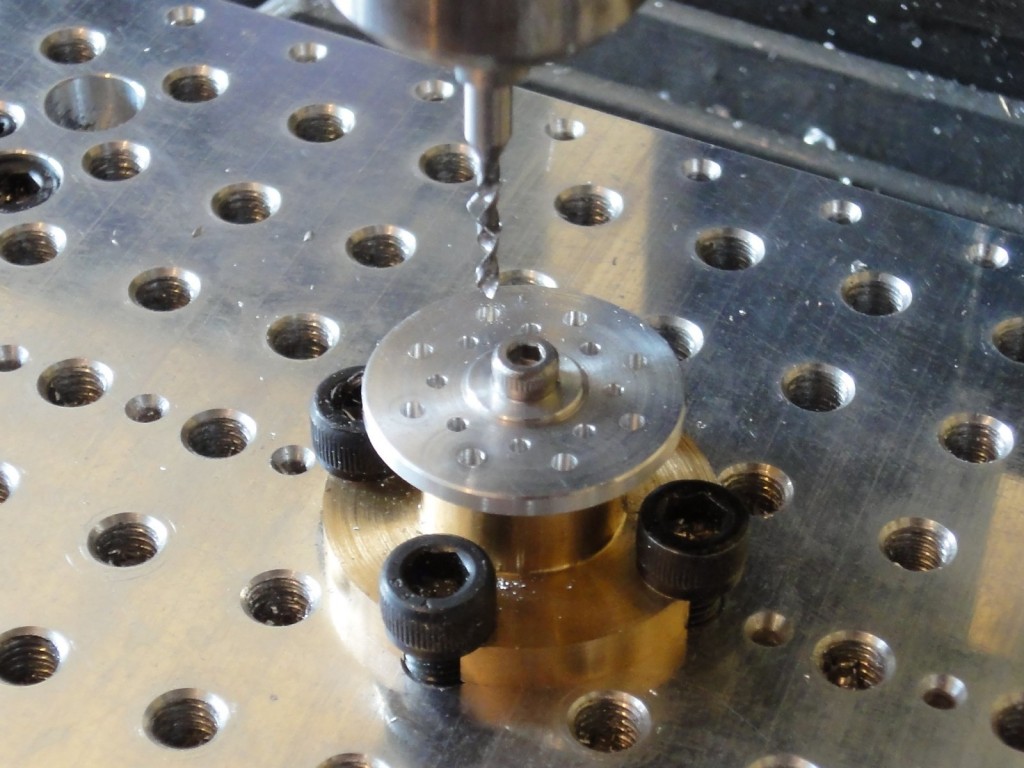

I almost decided to buy the 4 Flange Bearings FR07_F101 needed for a DARwIn-OP clone. But it just took me one afternoon to cut them on the lathe and drill them on a mill.

I tested the assembly of a bearing joint as described in the DARwIn-OP Assembly Manual. I haven’t anodize the parts and it seems I’ll have a hard time disassembling the joint, the bearing is very tight.

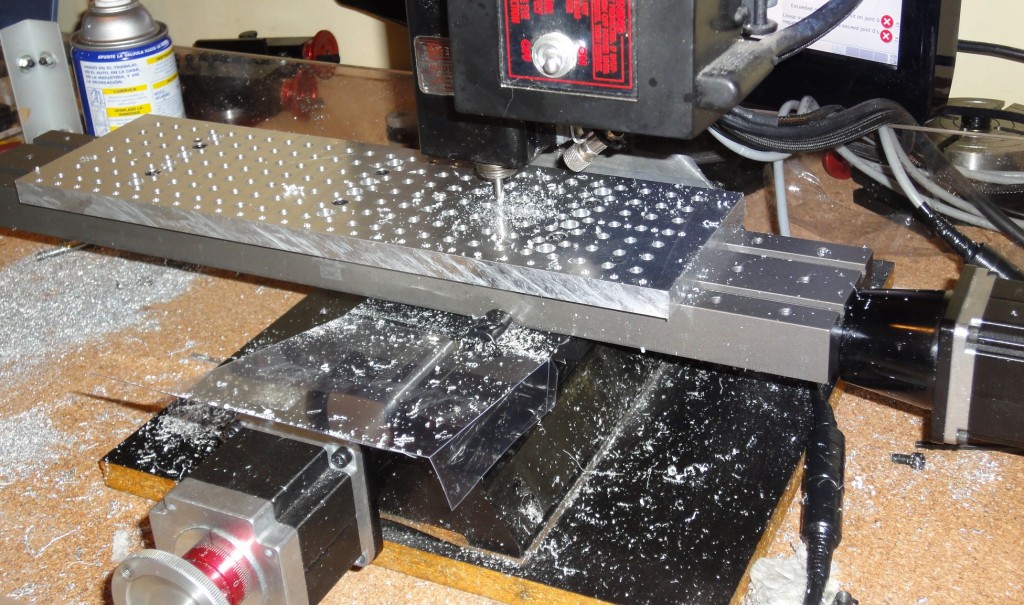

The gcode cut programs are in the Code Section and zipped in File Section in sourceforge repository for cloning the DARwIn-OP Robot.

Now I can continue testing the full assembly of a leg of my DARwIn-OP clone.