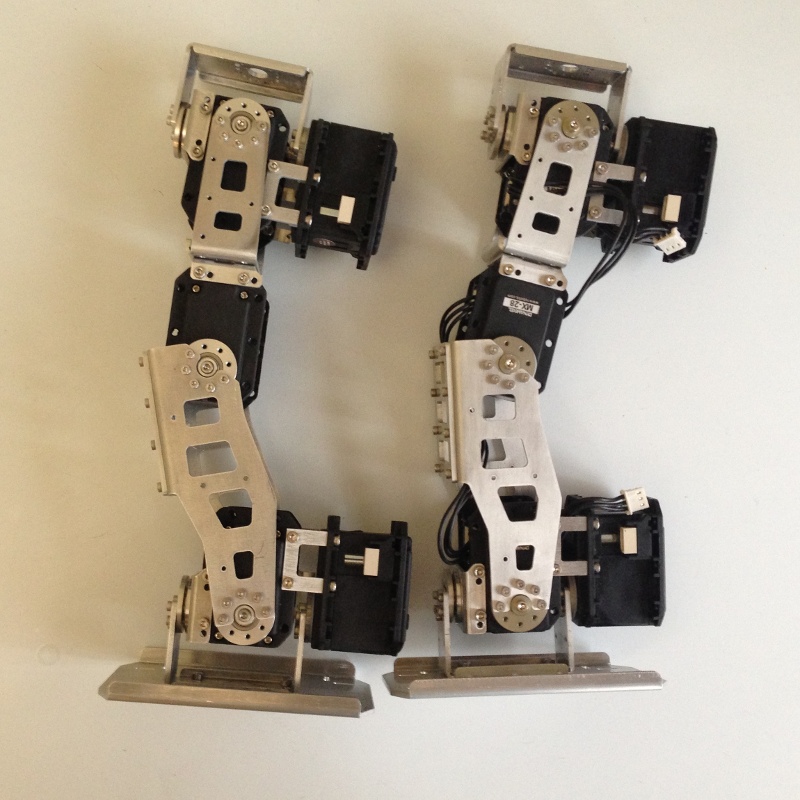

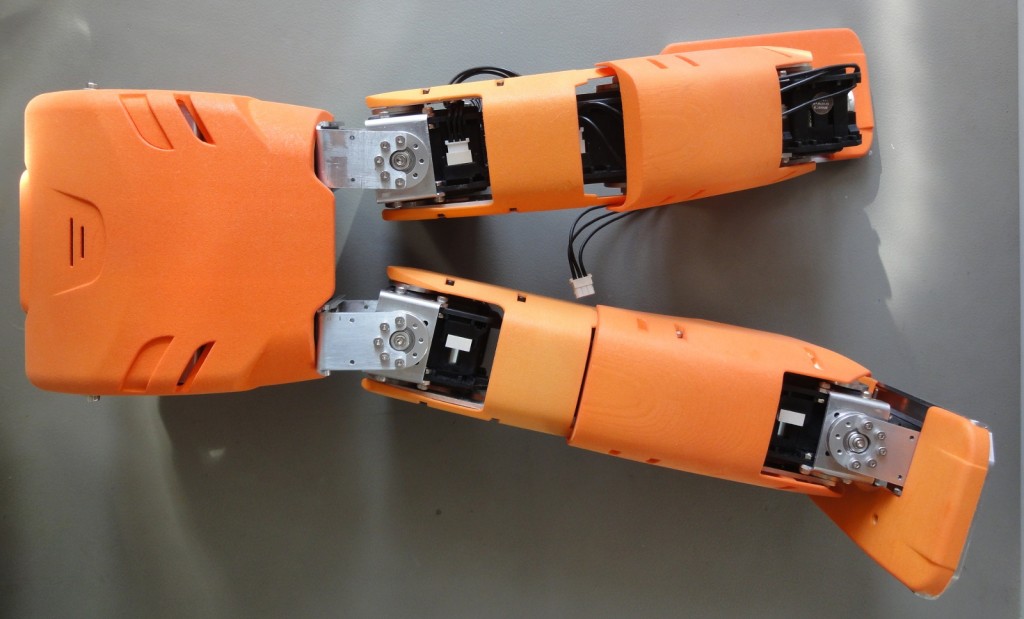

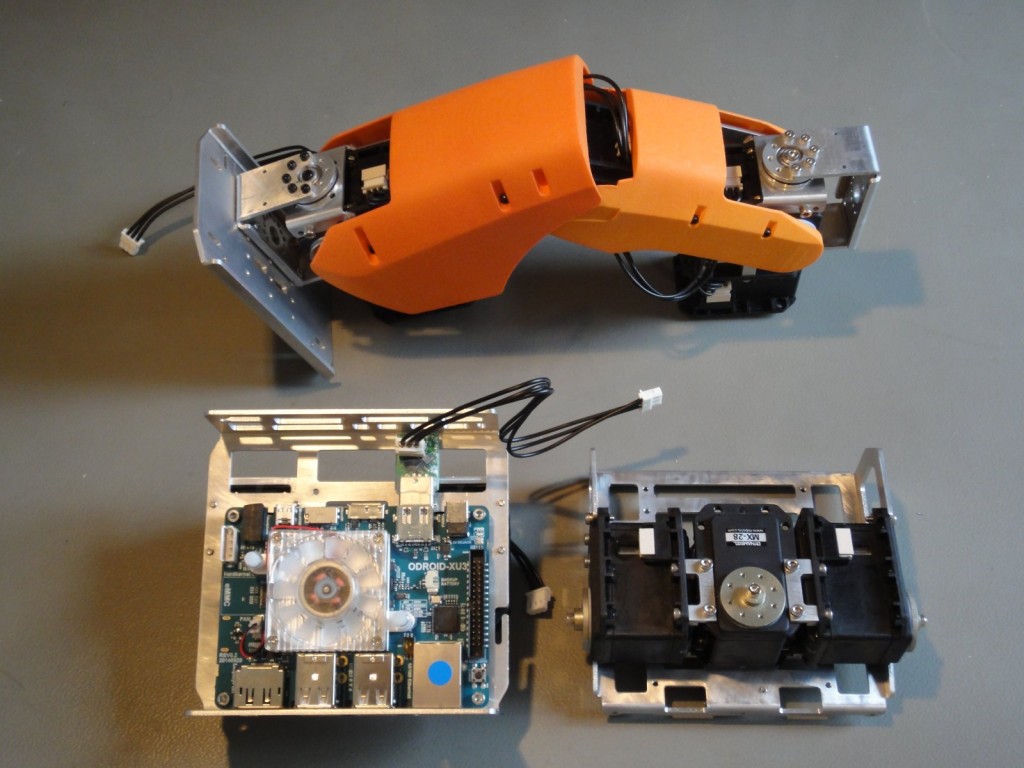

My DARwIn-OP clone is taking shape. I mounted the chest section.

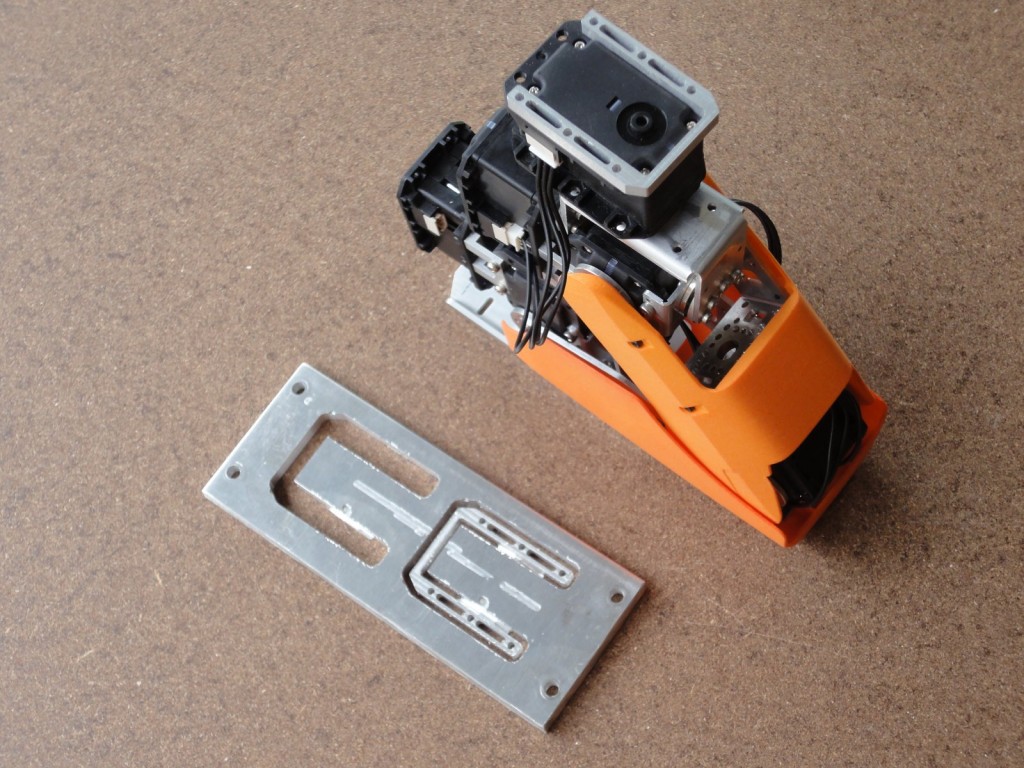

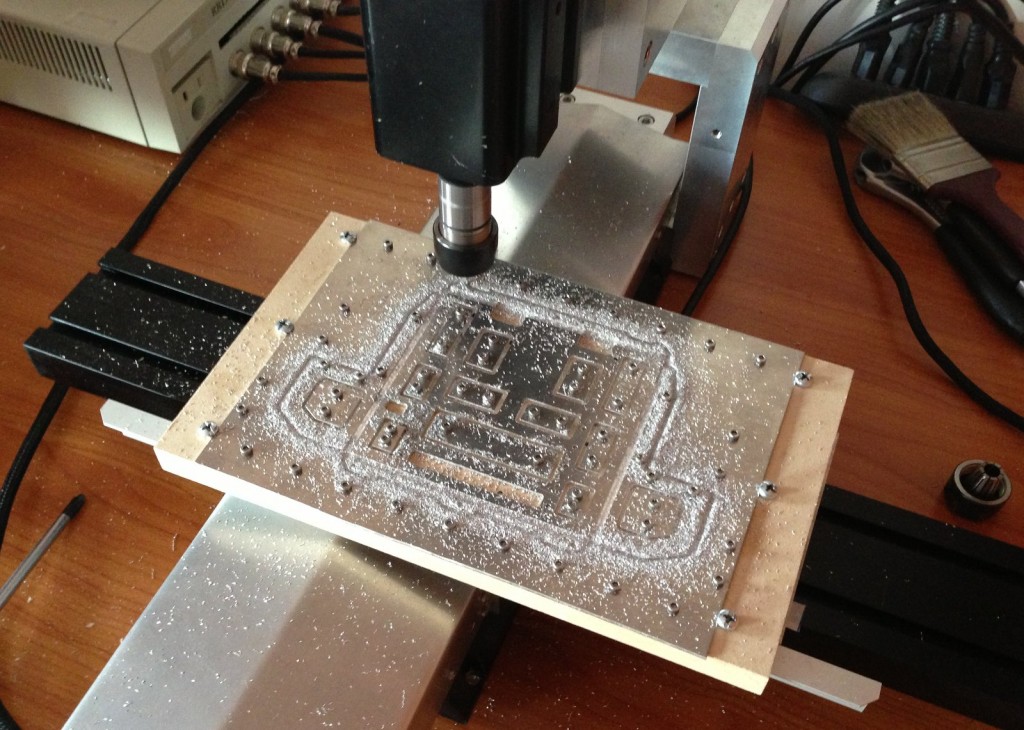

The chest parts (where the computer is mounted) are pretty big and my mill doesn’t have enough range in the Y axis to mill it in one cut. Luckily a friend that I met through this blog helped me with the cuts. He lives in my city and has a modified Sherline mill with bigger range. Also he is a Sherline dealer in Chile and works on CNC projects and has several interesting posts on his own blog at metaltronics.wordpress.com.

For the chest cuts, we tested using only a 1.5mm endmill, even for holes (1.6mm the smallest). For future cuts I will use bigger endmills such as 2mm o 2.5mm as in my previous cuts, the 1.5 endmill requires a depth of cut too small (we used 0.2mm) and are more fragile.

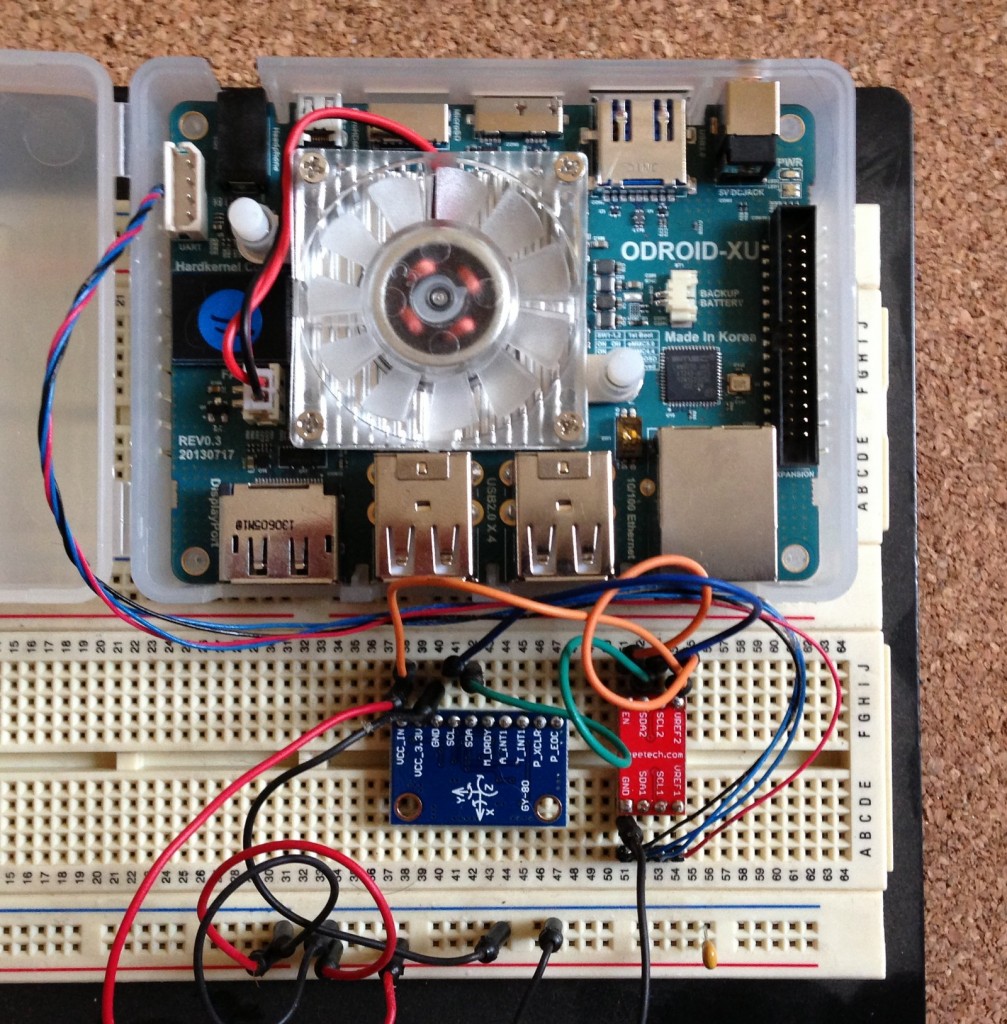

Since I am not going to use the original DARwIn-OP electronics (Fit-PC + CM-730 controller), I modified the chest parts to allow mounting an Odroid-XU3, in particular for access to the rear ports and mounting points.

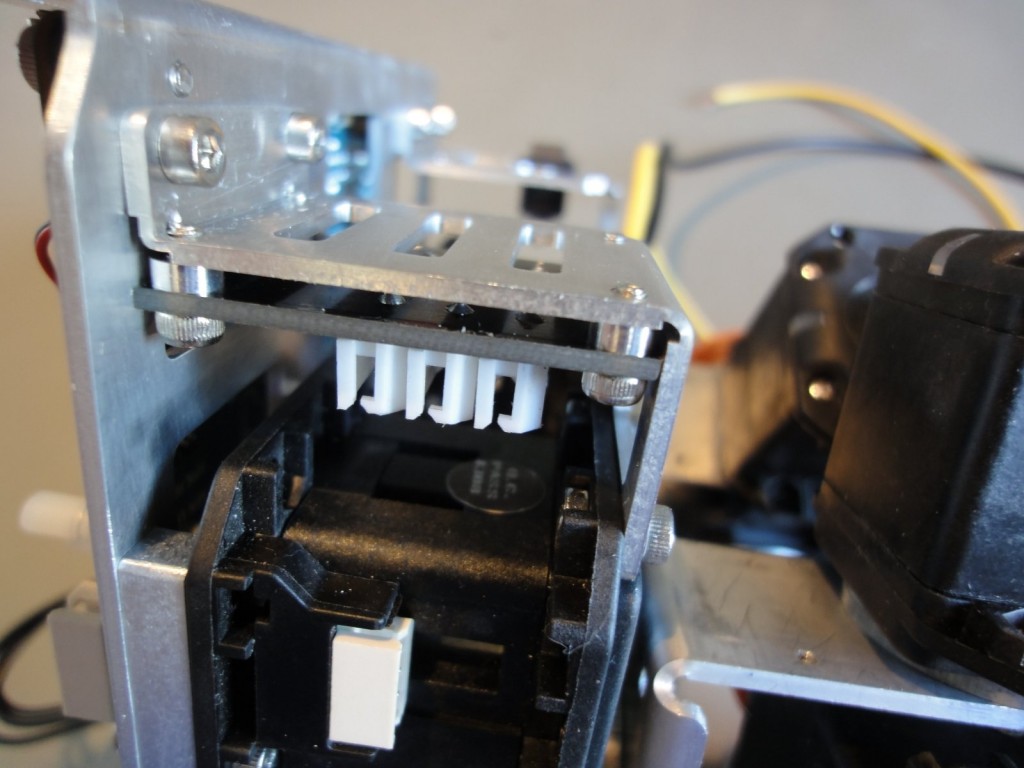

The Odroid-XU3 fits without problem, but to mount the USB2AX (interface to servos) I had to adjust the TTL connector to a vertical position.

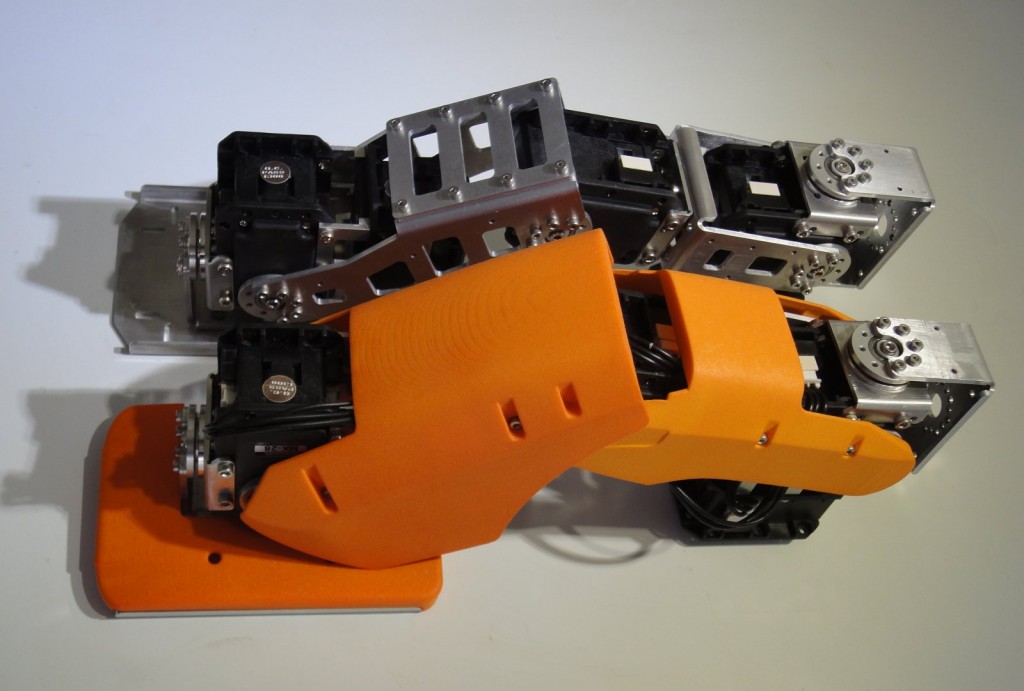

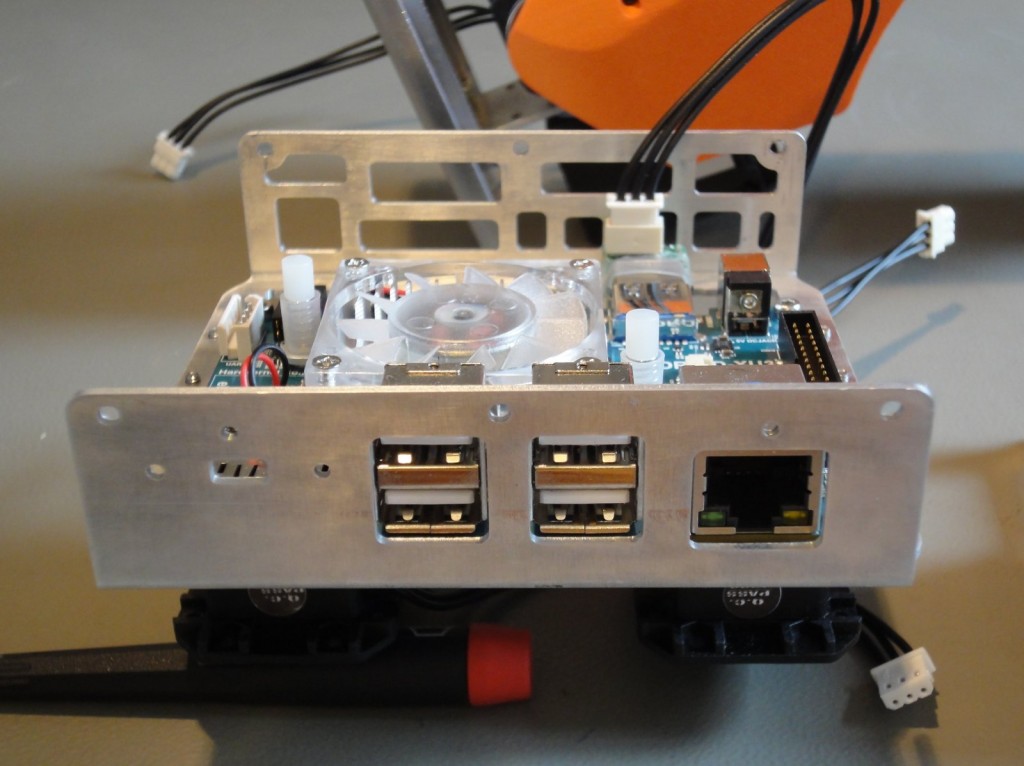

In the rear, I exposed the Ethernet port, 4 USB ports and a micro-HDMI (with a 15cm extender). Probably I’ll leave only 2 USB ports exposed, removing one connector to allow for more internal USB ports.

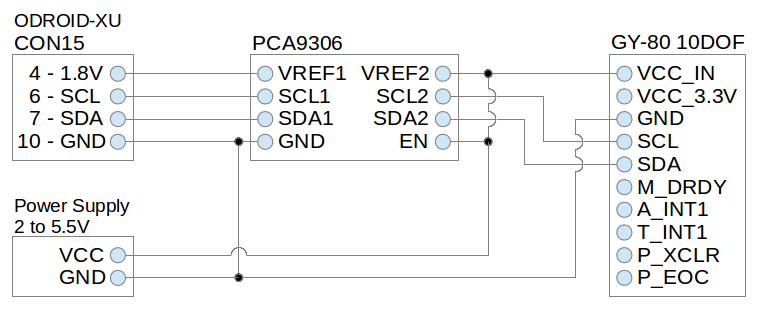

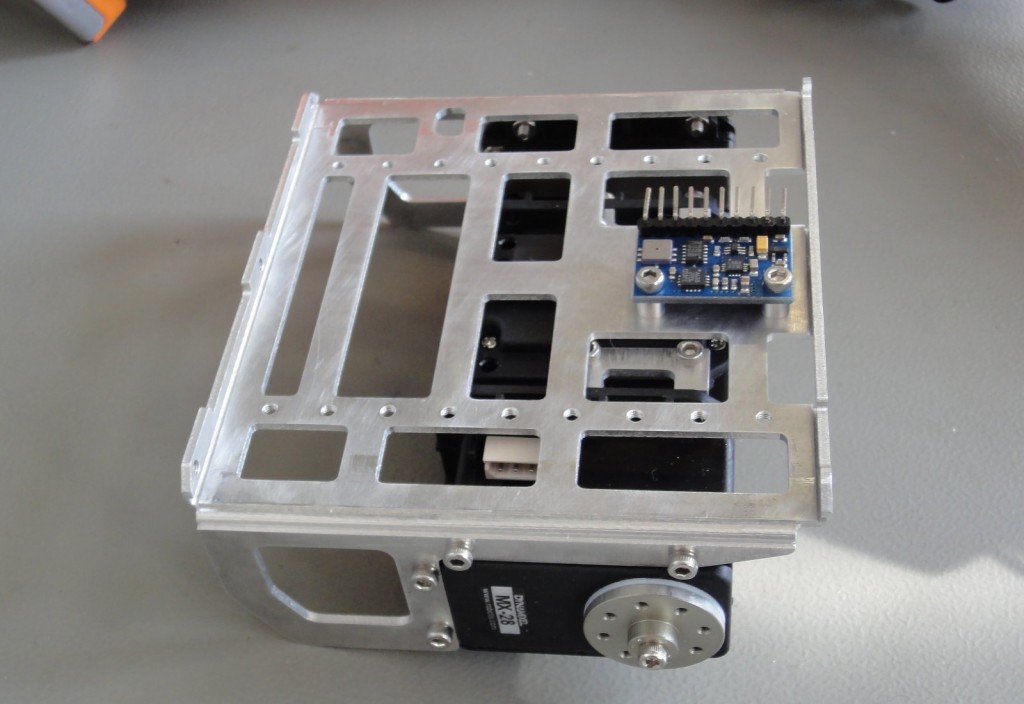

The upper chest part was modified to mount a 10-DOF, centering the accelerometer chip in the same place where the original CM-730 controller has its own. Additional holes tapped to 2.5mm were added for future components.

Because of the change of electronics, a 6 port TTL dynamixel hub is needed to connect the servos. In the rear there is just enough space to mounted.