Continuing with my DARwIn-OP clone robot, I am now cutting the shoulder parts.

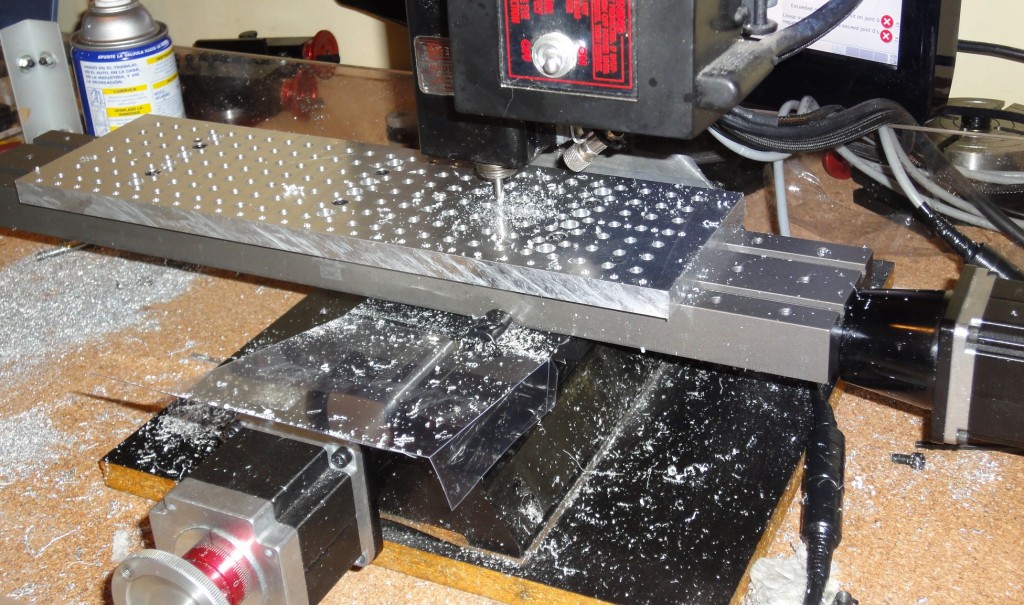

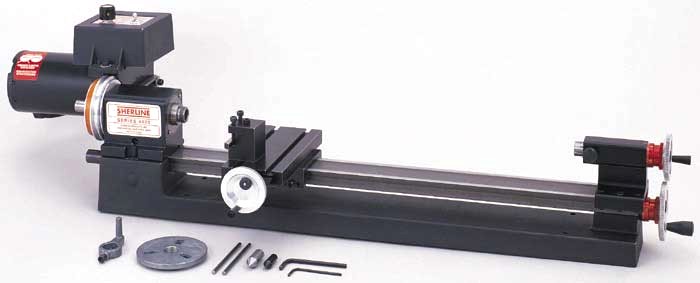

After most of the parts done, I am finally getting a better setup for cuts in my CNC Sherline mill.

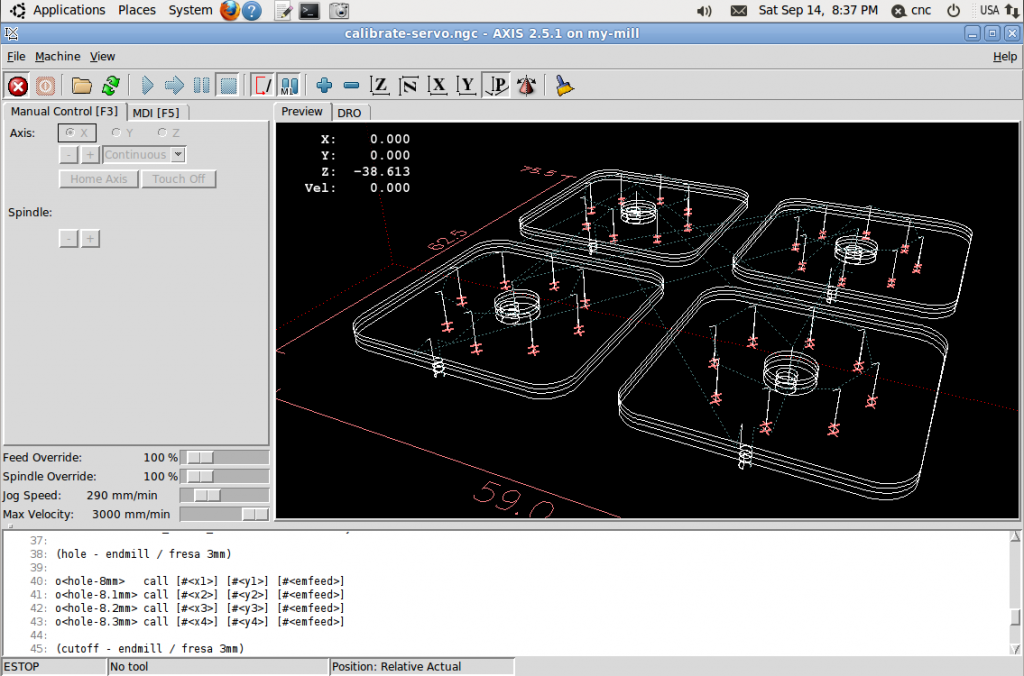

First I started fixing the aluminum sheets over small MDF board, cutting with 3mm endmills, a center drill, and several drills (1.6mm, 2.0mm, 2.05mm, 2.5mm, and 2.6mm), later I moved to a smaller 2.5mm endmill for better score’s finish. Following the DARwIn-OP Fabrication Manual, I placed checks on the cutoff path so the parts would not come loose. Later I replaced the MDF base board with an aluminum plate. Then I tested only using a single 1.5mm endmill for everything, but I didn’t like the surface finish and the holes weren’t perfect enough.

Now I think I have a better setup:

- Following a friend’s setup, I replaced my mill’s aluminum matrix plate with a MDF board with the same size and attachment.

- I fix the aluminum plates to the MDF board with several 2.5mm x 10mm screws around the parts to be cut. For this, I drill the MDF with a 2mm drill, 9mm deep. After several cuts, the MDF can easily be changed with another one.

- I went back to milling with a 2.5mm endmill (or 2mm endmill depending on the detail of the part, the Fabrication manual recommends a 3mm endmill, but some of the designs require 1mm radius cuts).

- I went back to using drills of size 1.6mm, 2.0mm, 2.05mm, 2.5mm, and 2.6mm. But since these are carbide drills with a wider (1/8″) shaft, I am not using a center drill any more to mark the holes. (After a few tests, I saw no hole displacements).

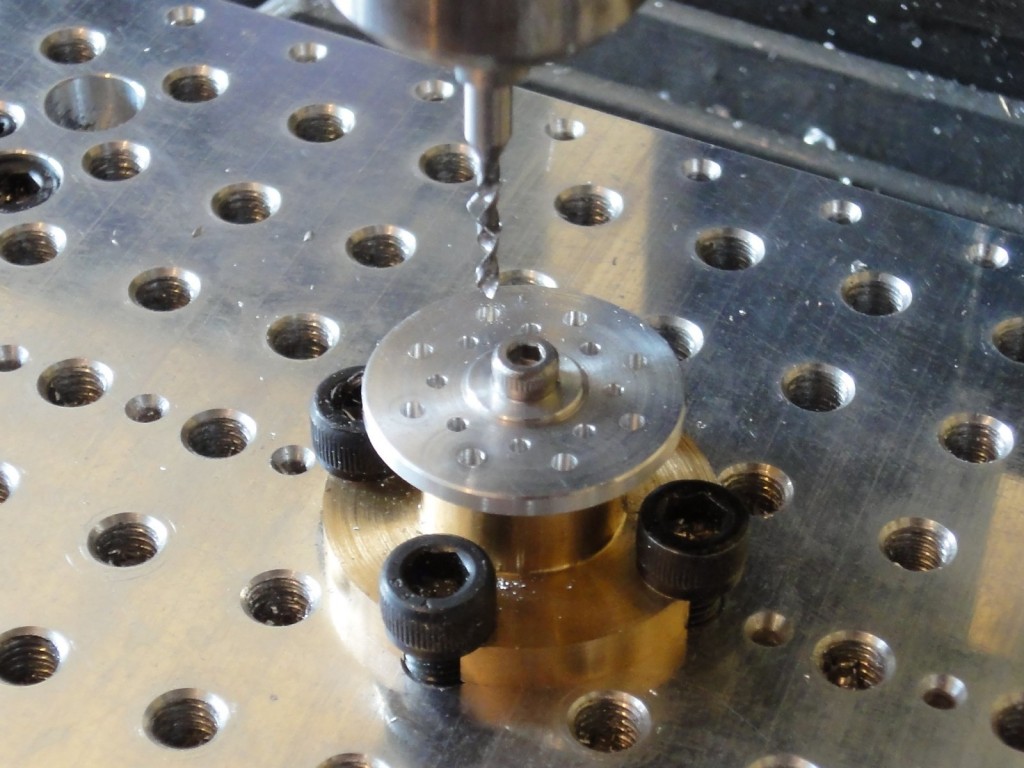

- I am not leaving checks on the cutoff paths anymore. Now I screw the part to the MDF before doing a complete cutoff. I use some of the original holes of the part for this.

- For any big slot that need to be emptied on a part, I mill it completely so no sizable aluminum bit that gets loose could break the endmill. If the slot is too big, then I would also place some screws on it so I don’t have to mill it all off.

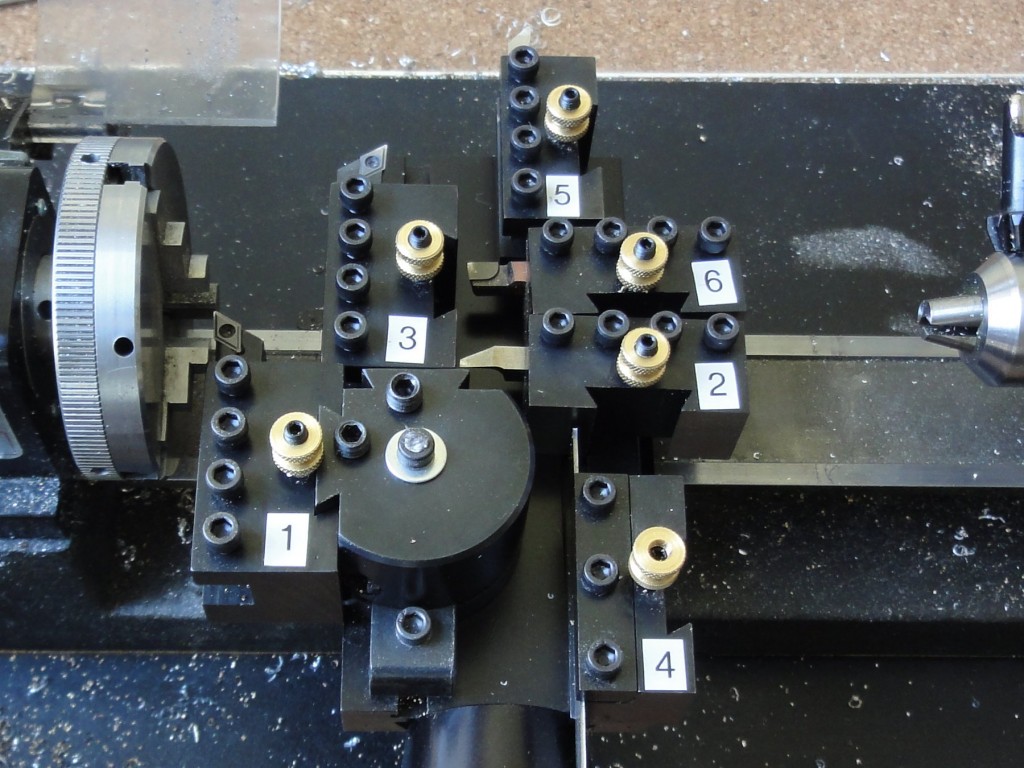

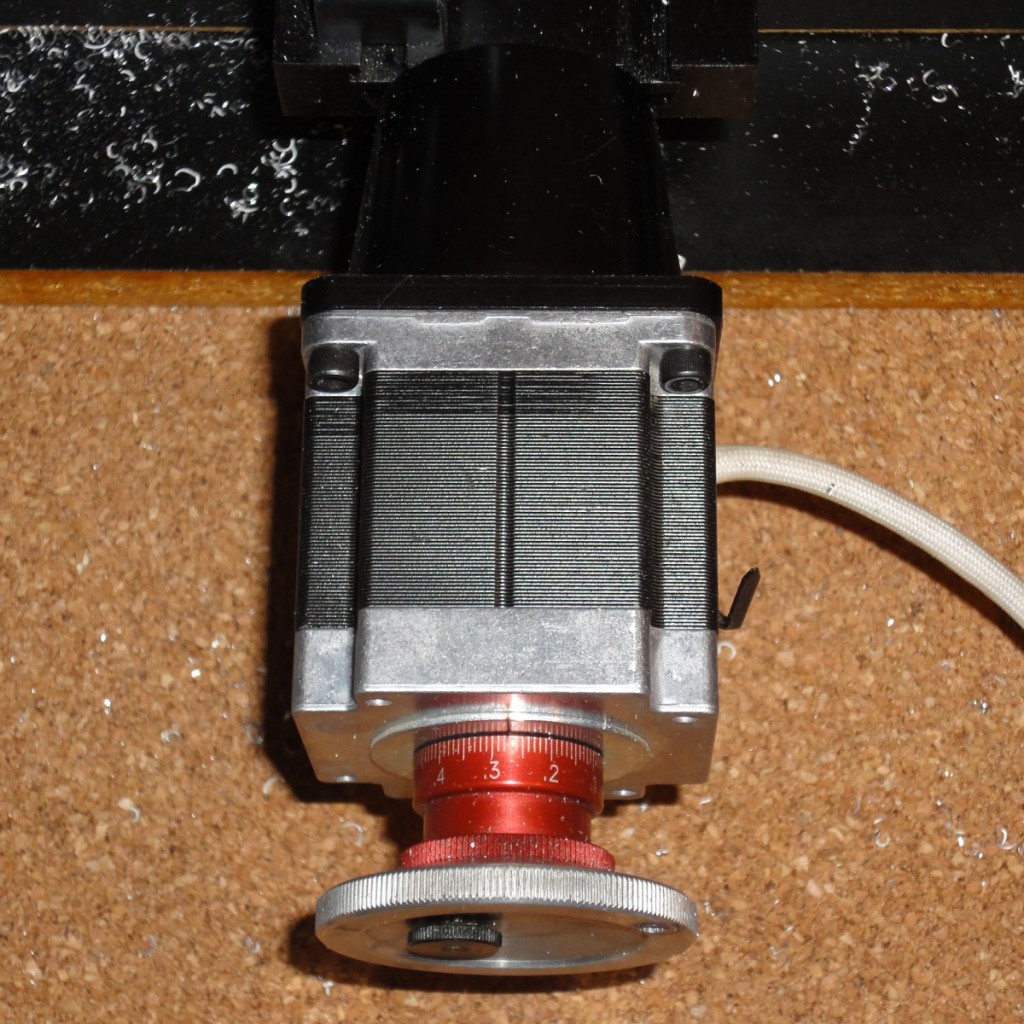

- Also, I replaced the Sherline mill headstock with an ER-16 model (from Sherline also). This allows for much easier tool changes, and ER-16 collets are available such as Techniks collets with very good accuracy (low TIR) which is important to keep small endmills well centered.

- I upgraded the mill to 10k RPM (with a 10k RPM pulley set from Sherline).

- I am cutting with the 2.5mm endmill at 5k RPM, 200mm/s speed, and 0.4mm depth of cut. For the 2mm endmill, I change the depth of cut to 0.25mm.

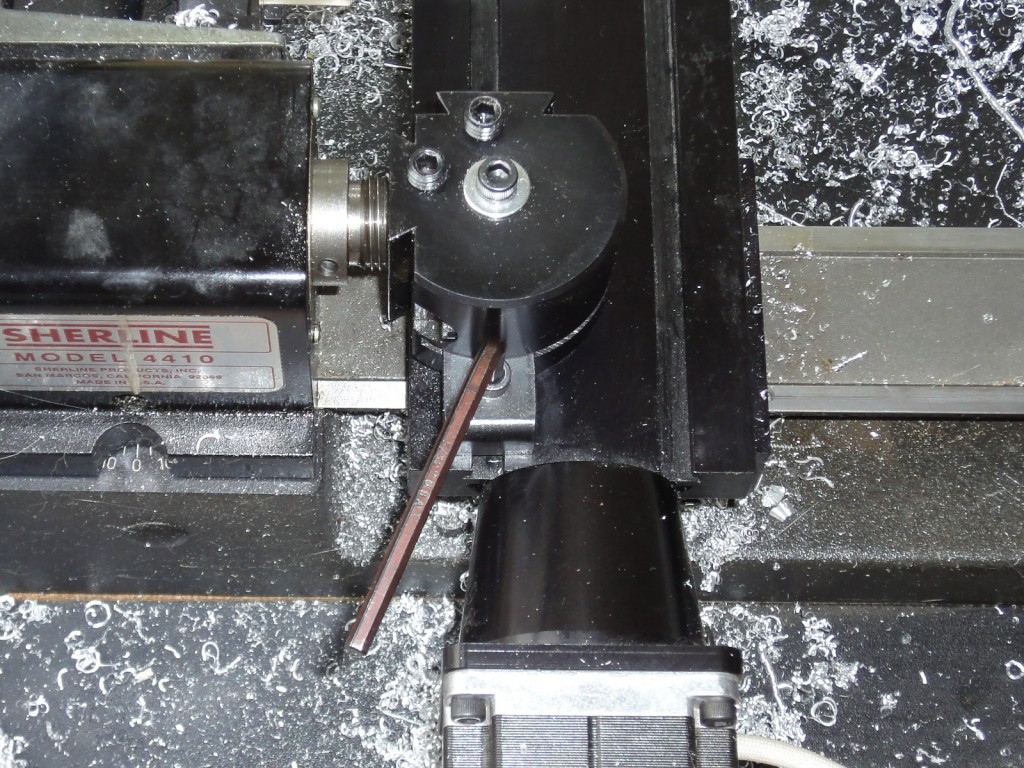

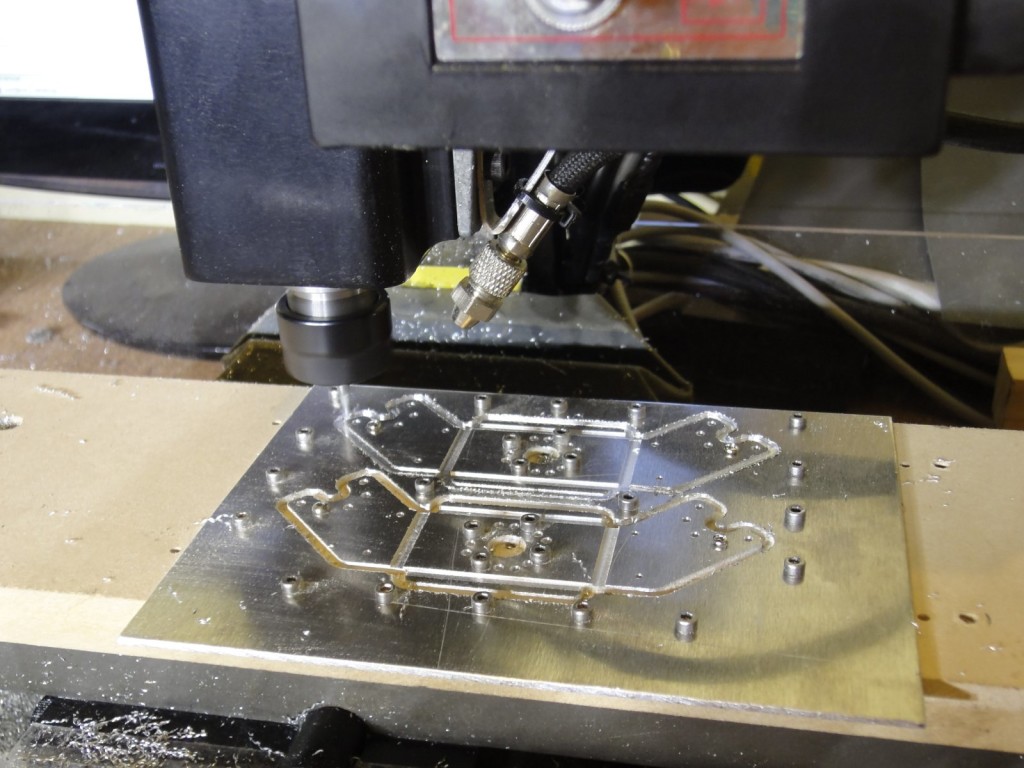

- I don’t use any lubricant, only an air blower to keep the cutting area clean (see photo).

The following picture shows the setup while milling the last cutoff:

The older gcode files I wrote don’t follow this setup, but can easily be updated.