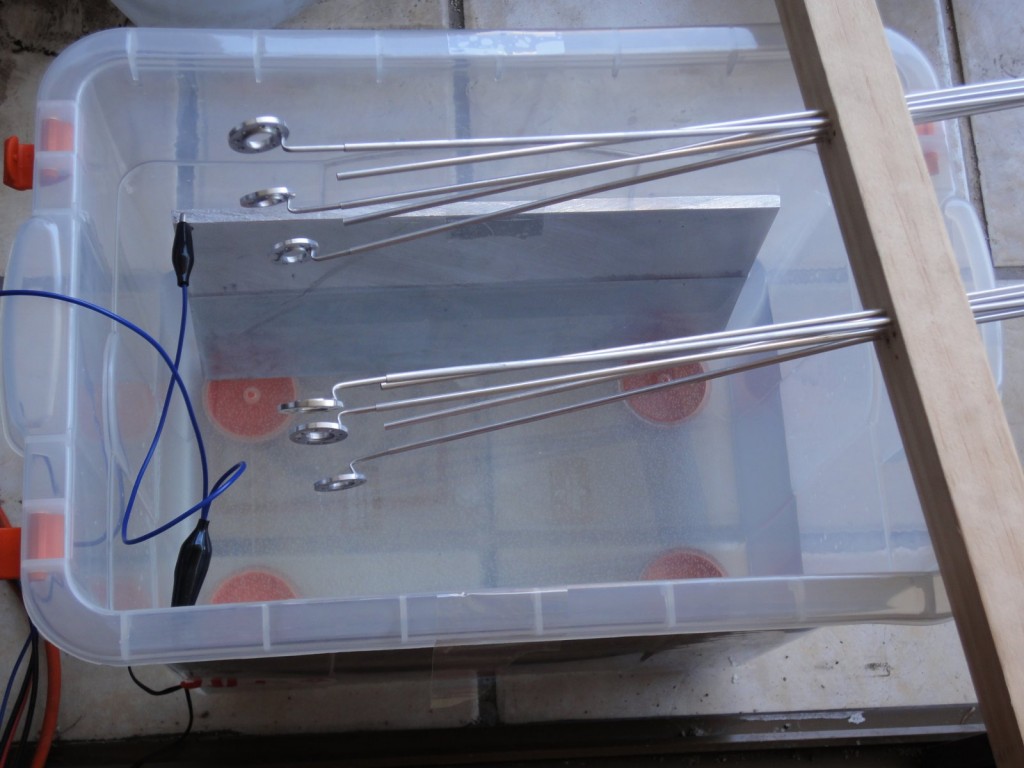

After doing some tests, I finished with all Idlers anodized. I am still waiting for some black dye to arrive, but the Idlers and Caps don’t use dye.

The process used was:

- Polish the parts.

- Wash the parts with soap and rinse in distilled water.

- 1 minute bath in sodium hydroxide (10g/L).

- 60 minutes of Type II anodizing: 12A/Ft² with 15% sulfuric acid (battery acid diluted 50/50 with distilled water) at 20°C.

- 30 minutes boiled in distilled water.

Since I did my first test cuts with some aluminum 2011, I used this test Idlers to try the anodizing process first. The surface finish will depend on the aluminum alloy used. With the 6061 alloy I got a nicer finish.

I did get some parts ruined with some anodizing marks, specially in a few Idler Caps. At least I have a few spares and they are easy to make. I saw in a tutorial video in YouTube that the parts are never clean enough to anodize them. Anyway, I need to do more research and tests before anodizing and dyeing the frames.

I will also test using a longer sodium hydroxide bath. The aluminum oxide buildup by anodizing is noticeable since the ball bearing fits tighter in the Idler, there is space for a longer bath (since it eats up some material).