Now that I checked that the Dynamixel MX-28T servos work OK and that it is easy to develop with the SDK, I am continuing with the rest of the first leg of my DARwIn-OP clone robot.

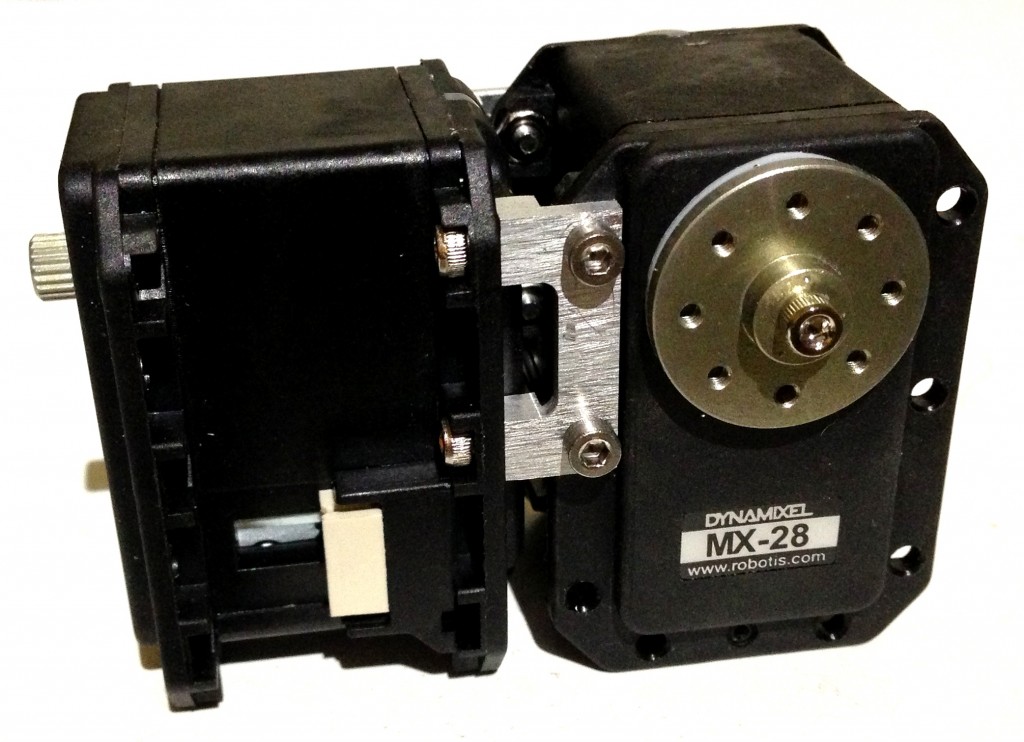

The FR07_X101 and FR07_X102 are actuator connectors for the legs and shoulders, they assemble together 2 servos to make a joint with two degrees of freedom. The DARwIn-OP requires 4 FR07_X101 and 8 FR07_X102. Acording to the design files and PDF specification from Robotis, they are 4.8mm high. I used a 1/4″ sheet as recommended in the Fabrication Manual, but a 5mm sheet should be better (less material to mill).

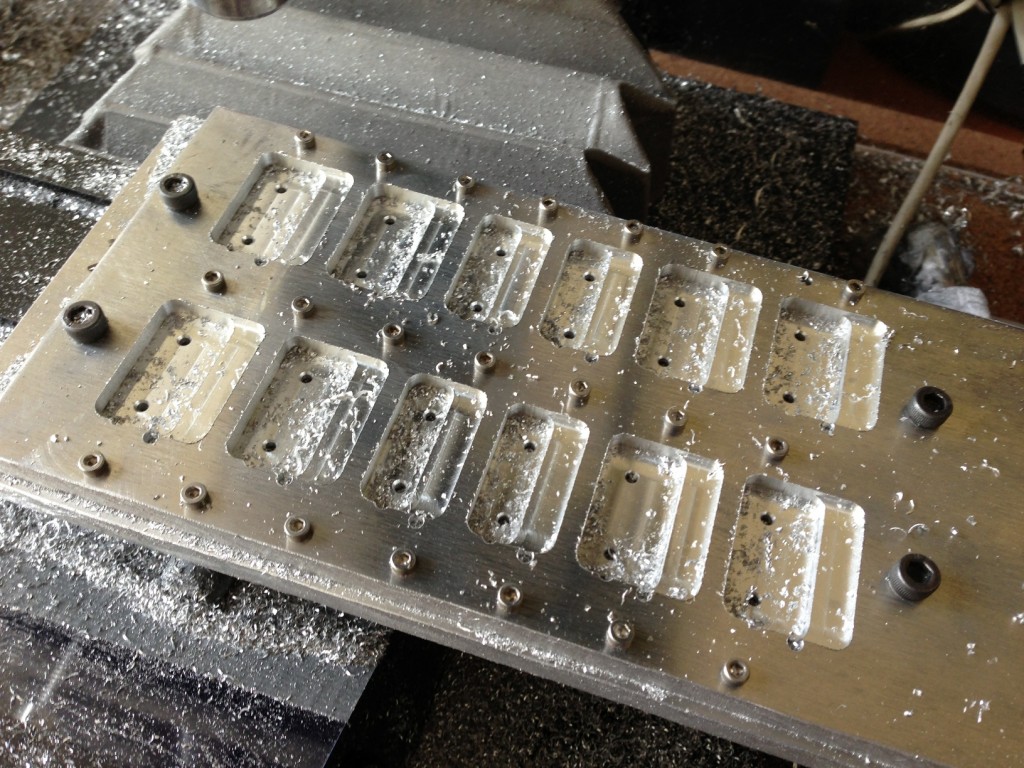

In this cut I started using an aluminum plate as base. I also started using rows of 2.5mm screws to better hold the work. This is not really needed to hold a 1/4″ sheet, but the 1.5mm and 2mm bend easily and small clearances between parts or to the sides may distort the cuts.

I also started to pre-cut the base plate in places where drills or the endmill would penetrate. So when the actual part is cut, the drill or endmill will not touch the base plate. This avoids material stacking up between the base plate and sheet that is getting cut, so the sheet doesn’t bend up. This can help sensitive cuts as the scores which should be 0.5mm deep for 2mm parts and 0.75mm deep for 1.5mm parts.

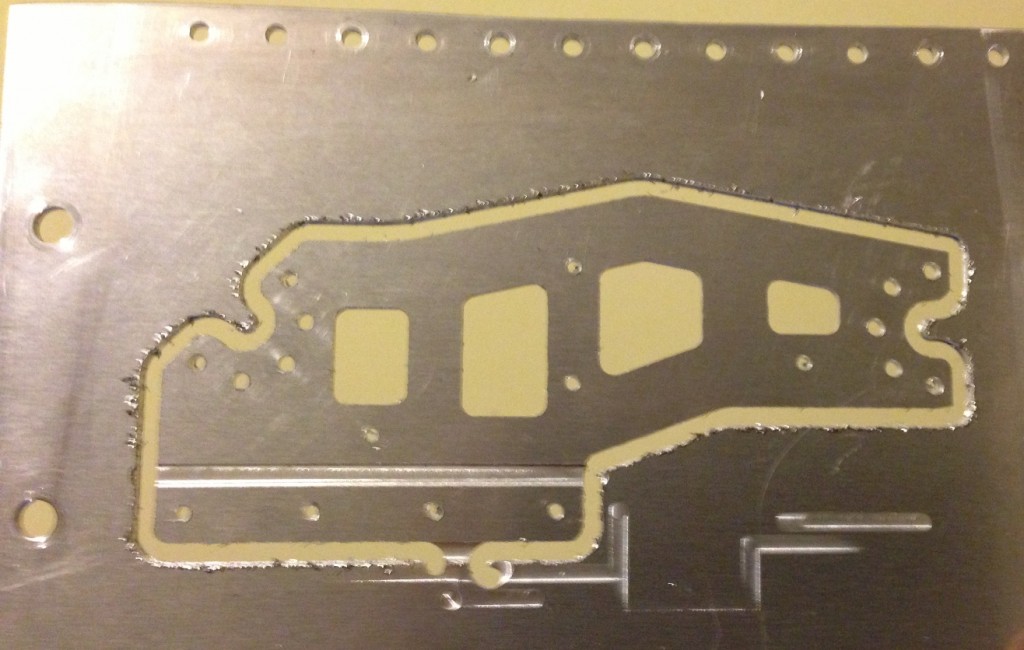

The the lower leg FR07_H133 are the most beautifully designed frames of the DARwIn-OP robot. I cut it in 3 parts as I explained in this earlier blog entry.

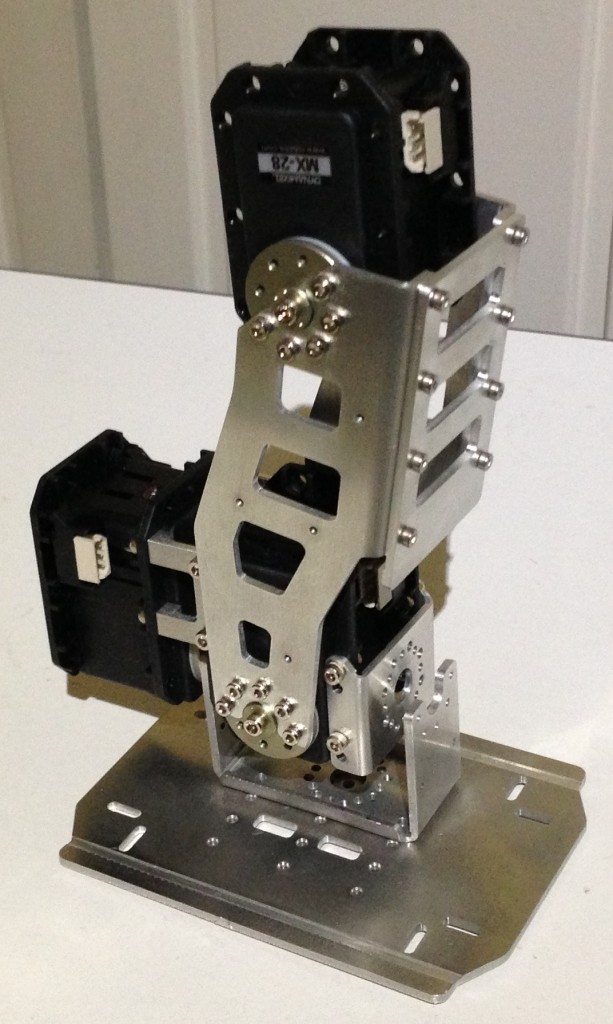

Now I can start testing the assembly of my DARwIn-OP clone. The frames are not polished nor anodized yet and they can get easily scratched. But this is an important step: I am too curious to see how it looks and if it fits together.

The lower leg assembled looks great, I am still missing some bends and some parts which I have to make in the lathe.

I could not use the 2D model files because they would give me incorrect sized frames and I had to redo the G-code cuts based on the 3D model files (See this post about it). So I’ll see if I get a response to this issue in the DARwIn-OP’s SourceForge Discussions before publishing the G-code files for the frames so far (I also need to clean up the files a little bit).