So, to continue with my DARwIn-OP Robot Clone, I need to make a few parts on the Sherline lathe.

For this, a quick change setup is really practical.

Using quick change tools allows to calibrate each tool once. Later, when cutting parts, the tools can be easily swapped in a few seconds, settling back again to the same positions with minimal margin of error.

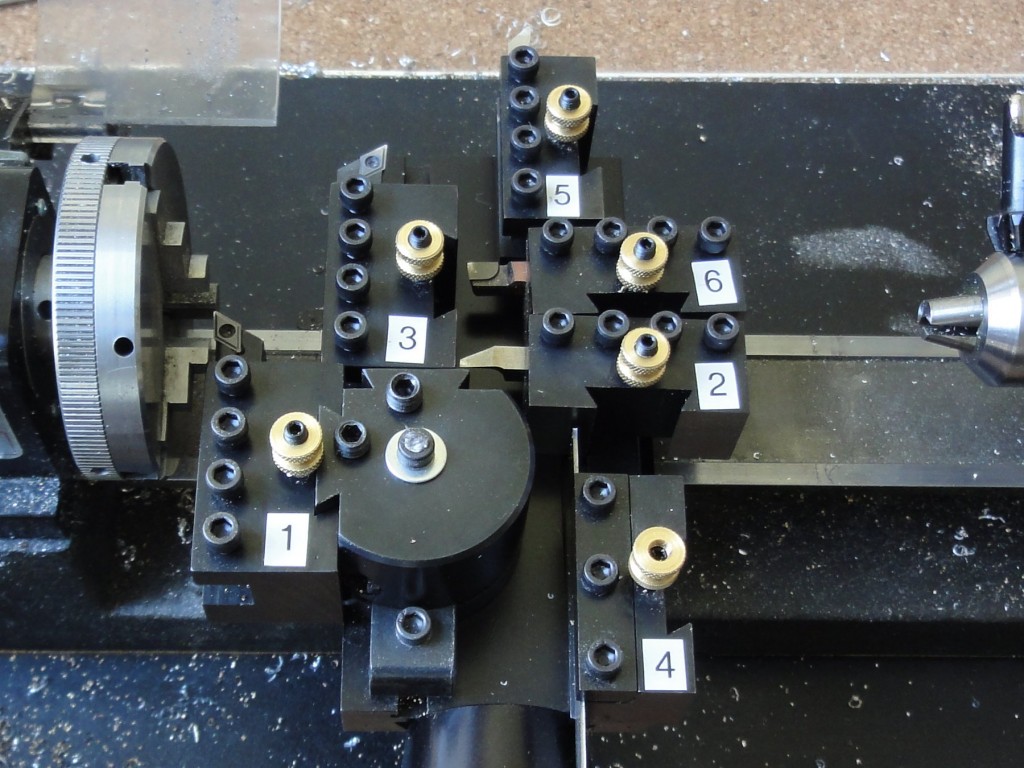

The basic tools I use are (updated):

- Right Hand Cutter (55° insert)

- Boring Cutter (for hole boring)

- Left Hand Cutter (55° insert for back face cutting)

- Cutoff Cutter (for cutting off the part from the stock metal)

- Left Hand Cutter (minimum radius tip for corners)

- Left Hand Cutter (in position for right facing)

- Right Hand Cutoff Cutter (tool #4 but calibrated for right and cutting)

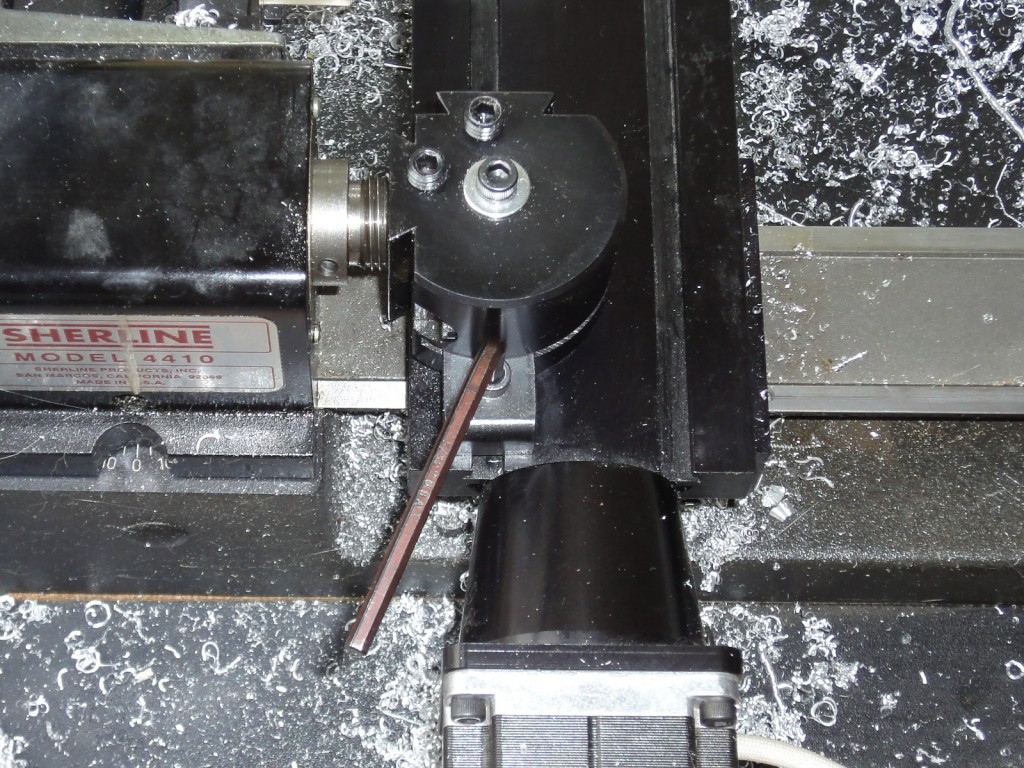

The quick change tool post must be aligned specially for the cutoff cutter to be aligned when cutting. I use the headstock to do the alignment.

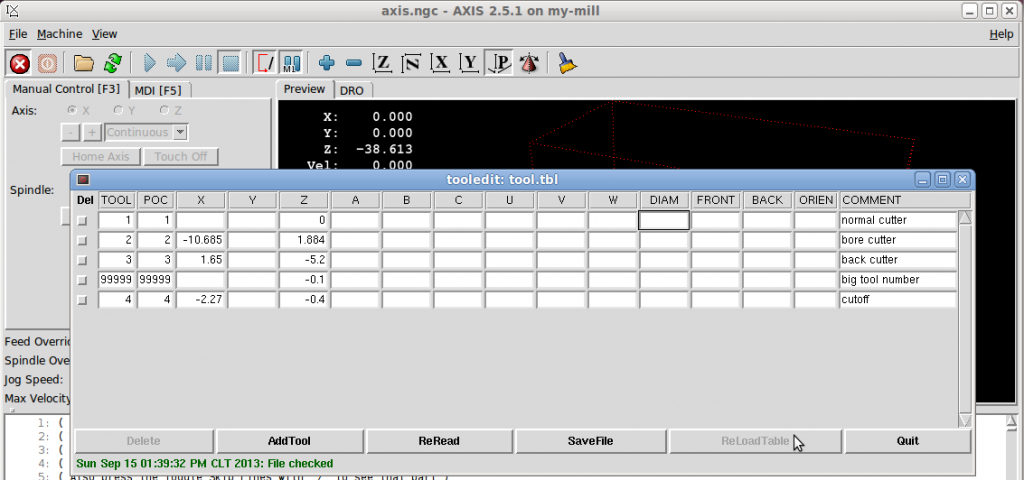

For CNC operation, the tools have to be configured in LinuxCNC’s tool table. So the software can compensate for the offsets for each tool.

Several test cuts have to be made to properly calibrate the tools X and Z offset, also the tool nose diameter can be setup to compensate on diagonal cuts.

Anyway, using a lathe (and a CNC version) have to be done cautiously. A wrong move could hit a cutter or its holder with the metal block you intend to cut and the CNC software won’t notice, plus the quick change tool post will get misaligned and all the calibration will have to be done again. It is also good to follow some safety guidelines like always turning off the lathe before switching tools or drills.